Industrial IoT Under Siege: Manufacturing Security Risks in 2026 Every Business Must Address

Executive Summary

Industrial IoT (IIoT) has revolutionized manufacturing, logistics, energy, and critical infrastructure — but it has also created catastrophic security vulnerabilities. 28% of manufacturing plants experienced IIoT breaches in 2026, and industrial cyberattacks surged 44% year-over-year. Unlike consumer IoT breaches that steal data, IIoT attacks cause physical damage: production lines stop, equipment fails, safety systems malfunction, and workers face real-world danger. With 33% of IIoT devices running outdated firmware and 52% of organizations lacking real-time monitoring, industrial environments are under siege. This comprehensive analysis reveals the five most dangerous IIoT attack vectors, the convergence crisis between IT and OT networks, and the battle-tested defense strategies that separate secure facilities from ransomware victims.

Why Industrial IoT Is the Ultimate High-Stakes Target

The Difference Between Consumer and Industrial IoT

Consumer IoT breaches:

- Privacy violation (cameras hacked)

- Data theft (personal information stolen)

- Financial loss (credit cards compromised)

- Annoyance (spam, slow devices)

Industrial IoT breaches:

- Production downtime (costs $120,000/hour on average)

- Physical equipment damage (explosions, fires, mechanical failures)

- Safety incidents (workers injured or killed)

- Supply chain disruption (cascading effects across industries)

- Environmental disasters (chemical spills, energy failures)

- National security threats (critical infrastructure attacks)

The stakes aren't just higher — they're existential for businesses and dangerous for workers.

The Numbers Tell a Grim Story

2026 Industrial IoT Threat Statistics:

- +44% year-over-year increase in IIoT cyberattacks

- 28% of manufacturing plants experienced IIoT breaches

- 37% surge in energy sector IoT attacks

- 33% of IIoT devices run outdated, vulnerable firmware

- 52% of organizations lack real-time IIoT monitoring

- 79% of enterprises now use IIoT (massive attack surface)

- 68% of manufacturing plants have IIoT sensors deployed

- $4.8-7.3 million average cost of industrial IoT breach

- 13-27 hours average operational downtime after IIoT incident

The Perfect Storm: Why IIoT Is Vulnerable

Legacy Systems:

- Industrial equipment designed 10-30 years ago (before cybersecurity concerns)

- No security features built-in (authentication, encryption, logging)

- Cannot be patched (would void warranties or break systems)

- Expected to run 20-40 years (far longer than IT systems)

Operational Technology (OT) Culture:

- Prioritizes uptime over security ("if it ain't broke, don't touch it")

- Change management extremely slow (patches delayed months/years)

- Air-gapped networks now connected for IIoT (breaking isolation)

- Security expertise scarce (OT engineers rarely have cybersecurity training)

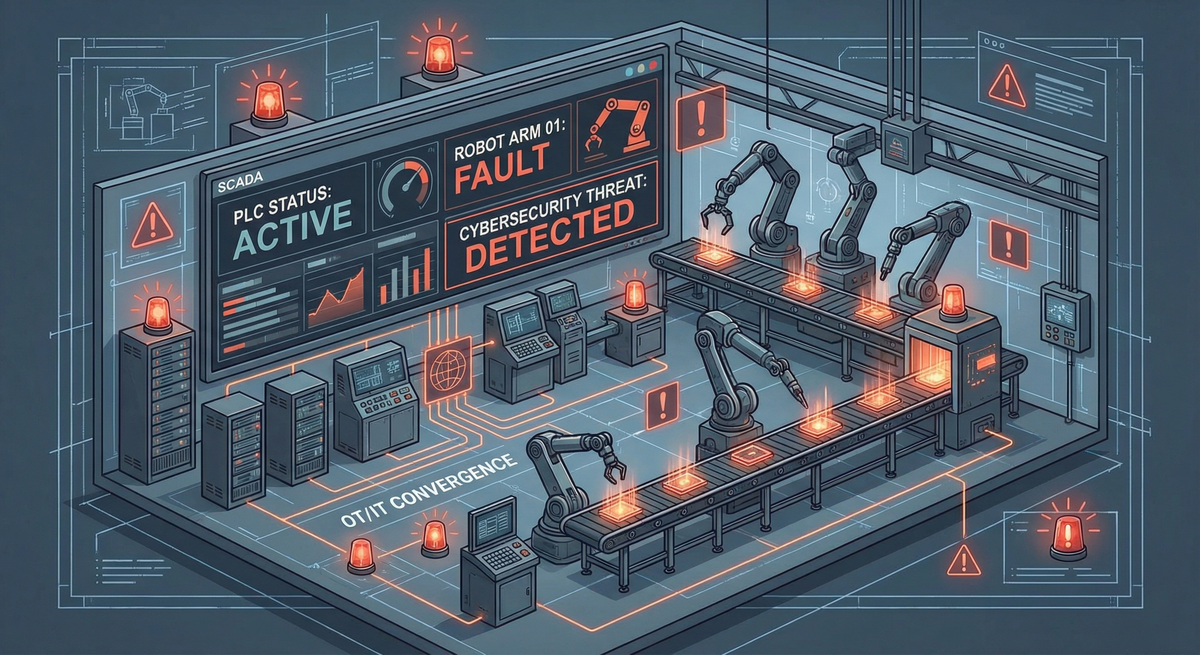

Convergence Crisis:

- IT and OT networks merging (for efficiency and data analytics)

- Creates bridges between secure IT and insecure OT

- Attackers pivoting from IT networks into industrial systems

- No clear ownership (IT or OT responsible for security?)

Economic Incentives for Attackers:

- Ransomware highly effective (downtime costs astronomical)

- Critical infrastructure pays biggest ransoms (cannot afford downtime)

- Nation-state attacks target industrial capabilities (sabotage, espionage)

- Insider threats lucrative (disgruntled employees, corporate espionage)

The Five Deadly IIoT Attack Vectors

Attack Vector 1: SCADA and PLC Manipulation — Taking Control of Industrial Systems

What Are SCADA and PLCs:

- SCADA (Supervisory Control and Data Acquisition): Software systems that monitor and control industrial processes

- PLC (Programmable Logic Controller): Hardware devices that directly control machinery (motors, valves, conveyors, robots)

Together, they form the "brain and nervous system" of industrial operations.

Why They're Vulnerable:

1. Weak or No Authentication

Many SCADA systems and PLCs were designed when:

- Networks were air-gapped (physically isolated)

- Only trusted employees had access

- Cybersecurity wasn't a consideration

Result:

- No password required to connect

- Default passwords ("admin/admin")

- No multi-factor authentication

- No role-based access control

2. Lack of Encryption

Industrial protocols (Modbus, DNP3, BACnet) transmit data in plain text:

- Commands visible to anyone on network

- Sensor readings intercepted

- Configuration changes observable

- No integrity checking (attackers can modify commands)

3. Unpatched Vulnerabilities

- 33% of IIoT devices run outdated firmware

- PLCs often cannot be patched without production downtime

- Vendors sometimes stop supporting older models

- Patching industrial systems requires extensive testing (months/years)

4. Network Connectivity

SCADA/PLC systems increasingly connected to:

- Corporate IT networks (for data analytics)

- Internet (for remote monitoring)

- Cloud platforms (for predictive maintenance)

- Third-party vendor networks (for support)

Each connection is a potential entry point.

Real-World Attack: The Water Treatment Plant Breach (2025)

Timeline:

Hour 0: Attacker gains access via phishing email (IT network)

Hour 3: Lateral movement from IT to OT network (weak segmentation)

Hour 8: SCADA system credentials stolen (default password "scada123")

Hour 12: Attacker accesses water treatment controls

Hour 14: Chemical dosage settings manipulated (100x increase in sodium hydroxide)

Hour 15: Plant operators notice unusual readings

Hour 16: Emergency shutdown initiated

Hour 18: Water supply to 300,000 residents disrupted

Week 1: System restored after forensic investigation

Total Cost: $8.2 million + public health crisis

What Attackers Can Do:

Manufacturing:

- Change production parameters (defective products)

- Override safety limits (equipment damage)

- Halt production lines (downtime)

- Alter quality control settings (product recalls)

Energy:

- Manipulate grid load balancing (blackouts)

- Disable safety shutoffs (explosions, fires)

- Alter transformer settings (equipment failure)

- Disrupt fuel delivery systems (supply shortages)

Water/Wastewater:

- Change chemical treatment levels (public health risk)

- Override pressure limits (pipe bursts)

- Disable alarms (incidents go undetected)

- Manipulate flow controls (flooding, shortages)

Transportation:

- Change traffic signal timing (gridlock, accidents)

- Manipulate railway switches (derailments)

- Override safety interlocks (collisions)

- Disable emergency braking (catastrophic failures)

Attack Vector 2: Production Line Disruption — Weaponizing Manufacturing Operations

How Modern Manufacturing Works:

Modern factories are highly automated:

- Sensors monitor temperature, pressure, speed, quality

- Robotics perform assembly, welding, painting, packaging

- Conveyor systems move materials automatically

- Industrial control panels coordinate all operations

- Quality control systems inspect products in real-time

All connected via IIoT networks.

The Attack Scenario:

Phase 1: Reconnaissance (Weeks 1-2)

Attacker maps the production network:

- Identifies sensors, PLCs, SCADA systems

- Documents production schedules

- Maps supply chain dependencies

- Identifies high-value targets

Phase 2: Initial Compromise (Week 3)

Attacker gains access via:

- Phishing email to employee

- Vulnerable VPN server

- Compromised third-party vendor

- Infected USB drive (left in parking lot)

Phase 3: Lateral Movement (Weeks 4-5)

From IT network, attacker pivots to OT:

- Exploits weak segmentation

- Steals OT credentials

- Compromises engineering workstations

- Gains access to industrial controllers

Phase 4: The Attack (Week 6)

Option A: Ransomware

5:00 PM Friday: Ransomware deployed across production network

5:02 PM: All PLCs, HMIs, SCADA servers encrypted

5:05 PM: Production line stops completely

5:10 PM: Ransom note appears: $15 million in Bitcoin

Result: Plant offline for 11 days, $47 million total cost

Option B: Sabotage

Production Line Attack:

- Robotic arm speed increased 300% (above safety limits)

- Result: Arm breaks, damages adjacent equipment

- Cost: $2.1 million in equipment damage + 19 days downtime

Quality Control Attack:

- Inspection parameters relaxed (defects pass as good)

- Result: 50,000 defective products shipped

- Cost: $18 million recall + brand damage

Safety System Attack:

- Emergency stop disabled on high-speed press

- Result: Worker injury when malfunction occurs

- Cost: Lawsuit + OSHA fines + plant shutdown investigation

Real-World Case: The European Aluminum Plant (2024)

Attack Summary:

- Target: Major aluminum manufacturing facility

- Entry: Spear-phishing email to maintenance contractor

- Impact: Production disrupted for 48 hours

- Damage: $2.9 million direct costs, $7.3 million revenue loss

- Method: Ransomware targeting industrial control systems

Why It Was Devastating:

Aluminum smelting requires continuous operation:

- Furnaces must stay at 960°C constantly

- Cooling damages equipment (takes weeks to restart)

- Sudden shutdown risked $50 million in equipment damage

- Company paid $1.2 million ransom to avoid worse outcome

Attack Vector 3: OT/IT Convergence Exploits — The Bridge Between Two Worlds

The Old Model: Air-Gapped Networks

Traditionally, OT and IT networks were completely separate:

IT Network:

- Computers, servers, email, internet

- Cybersecurity priority

- Regular updates

- Modern security tools

[AIR GAP - PHYSICAL SEPARATION]

OT Network:

- PLCs, SCADA, sensors, industrial equipment

- Uptime priority

- Rarely updated

- Minimal security

Attackers couldn't reach OT because it was physically disconnected.

The New Reality: Convergence

For business efficiency, companies connected networks:

IT Network ←→ OT Network

[BRIDGE CREATED]

Reasons:

- Real-time production data for analytics

- Remote monitoring for efficiency

- Predictive maintenance (AI/ML)

- Supply chain integration

- Cost savings (shared infrastructure)

Result: Attackers can now pivot from IT to OT.

Attack Path Example:

Step 1: Phishing email → IT employee's computer compromised

Step 2: Lateral movement → IT server accessed

Step 3: Exploit weak segmentation → Bridge to OT network discovered

Step 4: Credential theft → OT network credentials stolen

Step 5: OT access → Engineering workstation compromised

Step 6: ICS compromise → SCADA system controlled

Step 7: Physical impact → Production line disrupted

The Weakest Links:

1. Engineering Workstations

Computers used to program PLCs and configure SCADA:

- Connected to both IT (for email, internet) and OT (for programming)

- Often running outdated Windows (PLCs require old software)

- Rarely have antivirus (compatibility issues with industrial software)

- Used by multiple engineers (shared credentials)

Perfect pivot point for attackers.

2. Shared Databases

Production data stored in databases accessible from IT and OT:

- IT uses data for analytics, reporting

- OT uses data for process control

- Database server sits on network boundary

- Compromise gives access to both sides

3. Remote Access VPNs

Vendors need remote access for support:

- VPN credentials often weak or shared

- VPN servers sometimes poorly configured

- Vendors may have overly broad access

- Multiple vendors = multiple VPN accounts

Each vendor VPN is a potential attack vector.

4. Industrial IoT Gateways

Devices that bridge OT sensors to IT cloud platforms:

- Often have weak security (focus on functionality)

- Sit on network boundary

- Have access to both networks

- May have remote management interfaces

Case Study: The Colonial Pipeline Attack (2025 Variant)

Original Attack (2021):

- Ransomware via VPN compromise

- IT network encrypted

- OT unaffected but shut down preventively

- 5,500-mile pipeline offline 6 days

- $4.4 million ransom paid

2025 Variant (Hypothetical Escalation):

Had attackers reached OT systems:

- Pipeline controls manipulated

- Pressure settings altered (pipe ruptures)

- Safety systems disabled

- Environmental disaster potential

- Months to recover

- Billions in damage

The convergence risk is not theoretical—it's the #1 IIoT threat.

Attack Vector 4: Supply Chain Attacks — Poisoning From the Source

How Supply Chain Attacks Work:

Instead of attacking the target directly, attackers compromise:

- Equipment vendors (PLCs, sensors come pre-infected)

- Software providers (SCADA updates contain backdoors)

- Integrators/contractors (trusted partners used as entry points)

- Component manufacturers (firmware poisoned at factory)

Why They're Effective:

1. Trust Relationships

- Vendors have deep access to industrial networks

- Updates automatically trusted and installed

- Third parties bypass normal security controls

- Difficult to detect (looks like legitimate activity)

2. Scale

One compromised vendor can infect hundreds of customers.

3. Persistence

Backdoors embedded in firmware survive reboots, reinstalls, even hardware replacement (if burned into chips).

Real-World Examples:

Example 1: The SCADA Software Update (2024)

Attack:

- Hackers compromised SCADA software vendor

- Inserted backdoor into routine security update

- 340 customers automatically installed update

- Backdoor gave attackers remote access to industrial controls

Discovery:

- Detected 11 months after deployment

- By then, attackers had full network maps of 340 facilities

- 14 confirmed data breaches

- $290 million industry-wide remediation cost

Example 2: The PLC Firmware Backdoor (2025)

Attack:

- Nation-state actors compromised PLC manufacturer

- Backdoor embedded in firmware at factory

- Thousands of PLCs shipped with backdoor worldwide

- Backdoor activatable remotely (sleeper agent)

Implications:

- Critical infrastructure potentially controllable by foreign adversary

- Removing backdoor requires replacing all affected PLCs

- Billions in replacement costs

- Years to complete remediation

Supply Chain Vulnerability Points:

Component Manufacturer → Equipment Vendor → System Integrator → End User

[Backdoor] [Malware] [Compromise] [Victim]

Defense Is Difficult:

- Cannot verify every line of firmware code

- Trusted vendors difficult to audit

- Supply chain visibility limited

- No standard for secure industrial software development

Attack Vector 5: Insider Threats — The Enemy Within

Why Insider Threats Are Unique to IIoT:

1. Deep Access

Industrial employees have access to:

- SCADA systems (full control)

- PLCs (programming access)

- Safety systems (override capabilities)

- Network architecture (full knowledge)

External hackers spend months achieving what insiders have on day one.

2. Trust

- Insiders bypass security controls (trusted users)

- Actions assumed legitimate

- Anomalies attributed to errors, not malice

- Detection difficult (authorized access)

3. Motivation

- Disgruntled employees: Revenge for firing, disputes, perceived injustice

- Corporate espionage: Stealing trade secrets for competitors

- Financial gain: Ransomware, extortion, selling access

- Nation-state recruitment: Insider recruited by foreign intelligence

4. Knowledge

Insiders know:

- Which systems are most critical

- When attacks cause maximum damage

- How to hide their tracks

- Which defenses exist and how to bypass them

Real-World Case: The Disgruntled Engineer (2025)

Scenario:

Background:

- Senior engineer fired after 18 years

- Given 2 weeks notice (continued working)

- Maintained full system access during notice period

- Felt termination was unfair

The Attack:

Day 1 (Post-Firing Notice):

- Created backdoor account in SCADA system

- Encrypted credentials hidden in system logs

- Set to activate 30 days after termination

Day 14 (Last Day):

- Turned in access badge, laptop

- Company disabled AD account

- Backdoor account undetected

Day 45 (1 Month Later):

- Remote access via backdoor

- Production line parameters modified subtly

- Defect rate increased from 2% to 18%

- Quality control didn't catch pattern immediately

Week 8:

- 125,000 defective products shipped

- Major customer complaints

- Investigation launched

- $14 million recall + $8 million lost contracts

Insider Threat Statistics (2026):

- 19% of industrial security incidents involve insiders

- $250,000-2.1 million average insider threat cost

- 85 days average time to detect insider attack

- 57% of insider attacks involve privileged users (engineers, admins)

The Convergence Crisis: When IT and OT Collide

The merging of IT and OT networks has created a perfect storm of vulnerabilities.

The Cultural Divide

IT Mindset:

- Security first (C-I-A: Confidentiality, Integrity, Availability)

- Patch immediately (vulnerabilities must be closed)

- Change frequently (agile development, rapid updates)

- Downtime acceptable (scheduled maintenance windows)

OT Mindset:

- Uptime first (A-I-C: Availability, Integrity, Confidentiality)

- Patch carefully (testing takes months, cannot risk downtime)

- Change rarely ("if it works, don't touch it")

- Downtime catastrophic ($120k/hour, safety risks)

The Security Gap

IT Security Tools:

- Antivirus (signatures, behavior analysis)

- Firewalls (packet filtering, deep inspection)

- Intrusion detection (anomaly monitoring)

- SIEM (log aggregation and analysis)

- Vulnerability scanners (active probing)

OT Compatibility:

- Legacy protocols don't support encryption

- Active scanning can crash PLCs

- Signature updates might break systems

- Log formats often proprietary

- SIEM agents consume resources PLCs can't spare

Result: IT security tools cannot directly protect OT systems.

The Bridging Problem

Weak Segmentation:

Even when networks are "separated," bridges often exist:

- Engineering workstations

- Historians (databases collecting production data)

- MES (Manufacturing Execution Systems)

- ERP integration points

- Remote access VPNs

- Industrial IoT gateways

Each bridge is an attack path waiting to be exploited.

Building Industrial-Grade IIoT Defense

Defense Layer 1: Network Segmentation (Purdue Model)

What Is the Purdue Model:

The Purdue Enterprise Reference Architecture (PERA) defines network segmentation for industrial environments.

The 5 Layers:

Level 5: Enterprise Network (IT)

- ERP, email, internet, business systems

[DMZ / Firewall]

Level 4: Business Logistics

- MES, historians, production scheduling

[DMZ / Firewall]

Level 3: Site Operations

- SCADA, HMI, engineering workstations

[DMZ / Firewall]

Level 2: Area Control

- PLCs, distributed control systems (DCS)

[DMZ / Firewall]

Level 1: Basic Control

- Sensors, actuators, drives, I/O

[DMZ / Firewall]

Level 0: Physical Process

- Actual manufacturing equipment, machinery

Key Principles:

- Strict Segmentation: Each level isolated from others

- DMZ Zones: Data exchange happens in buffer zones

- Unidirectional Gateways: Data flows one way only (Level 2 → Level 3, never reverse)

- Defense in Depth: Multiple firewalls, each failure doesn't compromise entire network

Implementation:

Firewall Rules Example:

Level 5 (IT) → Level 4 (DMZ):

- ALLOW: Read production data (SQL queries)

- DENY: Write commands, configuration changes

Level 4 (DMZ) → Level 3 (SCADA):

- ALLOW: Monitoring data (read-only)

- DENY: Control commands, programming access

Level 3 (SCADA) → Level 2 (PLCs):

- ALLOW: Authorized engineering workstations only

- DENY: All other connections

- LOG: Every connection attempt

Level 2 (PLCs) → Level 1 (Sensors):

- ALLOW: Only configured PLC-to-sensor communication

- DENY: Internet access, external connections

Unidirectional Gateways:

Hardware devices that physically enforce one-way data flow:

- Data flows Level 2 → Level 3 (production data to IT)

- Commands CANNOT flow Level 3 → Level 2 (IT cannot reach OT)

- Even if compromised, cannot be used as reverse channel

Products:

- Waterfall Unidirectional Security Gateways

- Owl Cyber Defense Data Diodes

- Hirschmann EAGLE Tofino

Defense Layer 2: OT-Specific Security Monitoring

Challenges:

Traditional IT security tools don't work in OT:

- Signature-based detection misses industrial protocols

- Active scanning crashes PLCs

- Agents too resource-heavy for embedded systems

Solution: Passive Monitoring

Deploy sensors that observe traffic without interacting:

How It Works:

Production Network

↓ (network tap, mirror port)

OT Security Monitor (passive sensor)

↓ (analyzes traffic)

Alert System

What It Detects:

- Unauthorized connections (unknown devices, unexpected sources)

- Protocol anomalies (malformed packets, unusual commands)

- Behavioral changes (devices communicating differently than baseline)

- Unauthorized configuration changes (PLC programming during non-maintenance hours)

- Lateral movement attempts (unusual network traversal patterns)

OT Security Platforms:

- Nozomi Networks — Industrial cybersecurity leader, AI-powered threat detection

- Claroty — OT visibility and threat detection

- Dragos Platform — Threat intelligence for industrial control systems

- Armis — Agentless device security

- Forescout — OT network access control

Benefits:

- No impact on production (100% passive)

- Real-time threat detection

- Asset inventory (discovers all devices automatically)

- Vulnerability assessment (identifies unpatched systems)

- Compliance reporting (documents security posture)

Defense Layer 3: Zero Trust for OT

Traditional OT Security:

"Trust but verify" — devices inside OT network trusted by default.

Zero Trust OT:

"Never trust, always verify" — every connection authenticated, authorized, encrypted.

Core Principles:

- Least Privilege Access: Users/devices only access what they absolutely need

- Continuous Authentication: Every connection validated, not just at login

- Micro-Segmentation: Devices isolated even within OT zones

- Encryption: All traffic encrypted (even inside secure zones)

- Monitoring: Every action logged, analyzed

Implementation:

Step 1: Asset Inventory

Document every device:

- PLCs, sensors, SCADA servers, HMIs, engineering workstations

- Firmware versions, network addresses, communication protocols

- Data flows (what talks to what, when, why)

Step 2: Define Access Policies

Policy Example:

Device: PLC-Line-3 (192.168.10.23)

Allowed to communicate with:

- SCADA-Server-1 (192.168.10.5) - read-only, Modbus TCP

- HMI-Station-2 (192.168.10.15) - read-only, OPC-UA

- Engineering-WS-1 (192.168.10.50) - read/write, only during maintenance windows

Deny all other connections.

Step 3: Enforce Policies

Use next-gen firewalls with deep packet inspection (DPI):

- Palo Alto Networks (OT Security Suite)

- Fortinet (FortiGate ICS/SCADA Firewalls)

- Cisco (Industrial Security Appliances)

Step 4: Continuous Monitoring

Deploy OT-specific SIEM:

- Splunk (Industrial IoT app)

- IBM QRadar (OT module)

- Nozomi Networks Guardian

Defense Layer 4: Secure Remote Access

The Problem:

Vendors need remote access for:

- Troubleshooting

- Software updates

- Preventive maintenance

- Emergency support

Traditional approach: VPN with shared credentials

- Weak passwords

- Broad access

- Difficult to revoke

- No activity monitoring

Zero Trust Remote Access:

1. Identity Verification

- Multi-factor authentication required

- Unique credentials per vendor (no sharing)

- Certificate-based authentication

- Time-limited access (expires after session)

2. Least Privilege

- Vendor only accesses specific systems

- Read-only unless write justified

- Session recording (every action logged)

- Real-time monitoring (security team watches)

3. Just-In-Time Access

- Access granted only when needed

- Approval workflow required

- Automatic revocation after time limit

- No persistent credentials

Implementation:

Products:

- BeyondTrust (Privileged Remote Access)

- CyberArk (Secure Remote Access)

- Dispel (Virtual Air-Gapped Network)

Example Workflow:

Vendor requests access:

1. Submit ticket: "Need to update PLC firmware, Line 3"

2. Manager approves (specifies scope, duration)

3. MFA authentication required

4. Certificate issued (valid 4 hours)

5. Access granted to PLC-Line-3 ONLY

6. Session recorded (video + commands)

7. Access auto-revoked after 4 hours

8. Audit log generated

Defense Layer 5: Insider Threat Detection

Technical Controls:

1. Privileged Access Management (PAM)

- Require approval for critical actions (programming PLCs, changing SCADA configs)

- Session recording (video of every privileged session)

- Credential vaulting (passwords not known to users, retrieved just-in-time)

- Break-glass procedures (emergency access with automatic alerts)

2. User Behavior Analytics (UBA)

AI learns normal behavior for each user:

- Which systems they access

- When they typically log in

- What actions they perform

- Data they download

Alerts on anomalies:

- Access at unusual times

- Accessing unusual systems

- Excessive data downloads

- Configuration changes outside maintenance windows

3. Data Loss Prevention (DLP)

Monitor for exfiltration attempts:

- Large file transfers

- Copying data to USB drives

- Emailing sensitive files

- Uploading to cloud services

Operational Controls:

1. Background Checks

- Pre-employment screening

- Periodic re-checks (every 3-5 years)

- Credit checks (financial stress = motivation)

- Social media monitoring (public threats, grievances)

2. Separation of Duties

- No single person has complete control

- Programming PLCs requires two engineers

- Critical changes require manager approval

- Peer review of all configuration changes

3. Offboarding Procedures

When employee terminated:

Hour 0: Termination meeting

Hour 1: Escort from facility

Disable all access immediately (AD, VPNs, badges)

Collect laptop, badge, keys

Hour 2: Change passwords on systems employee accessed

Review recent activity logs for anomalies

Hour 24: Full audit of employee's access history (past 90 days)

Week 1: Search for backdoor accounts, hidden credentials

Monitor for access attempts from external IPs

Conclusion: The Industrial Security Imperative

Industrial IoT has created unprecedented efficiency gains—but also unprecedented risks. The consequences of IIoT breaches aren't abstract: production stops, workers get injured, environmental disasters occur, and companies go bankrupt.

The numbers don't lie:

- 28% of plants breached in 2026

- $4.8-7.3 million average cost per incident

- 13-27 hours downtime per attack

- 44% year-over-year attack increase

Traditional IT security is inadequate for OT environments. Industrial systems require specialized security strategies: Purdue Model segmentation, passive monitoring, Zero Trust architecture, and insider threat programs.

The choice is stark:

- Invest in IIoT security now and maintain operations

- Ignore the threat and become the next headline

Action Plan

This Week:

- [ ] Audit IT/OT network connections

- [ ] Identify all bridging points

- [ ] Document IIoT asset inventory

- [ ] Review vendor remote access policies

This Month:

- [ ] Deploy passive OT security monitoring

- [ ] Implement network segmentation (start with Level 3/4/5)

- [ ] Establish privileged access management

- [ ] Train OT staff on cybersecurity basics

This Quarter:

- [ ] Full Purdue Model implementation

- [ ] Zero Trust pilot program

- [ ] Insider threat detection deployment

- [ ] Incident response plan development

Protect your industrial operations before attackers do.